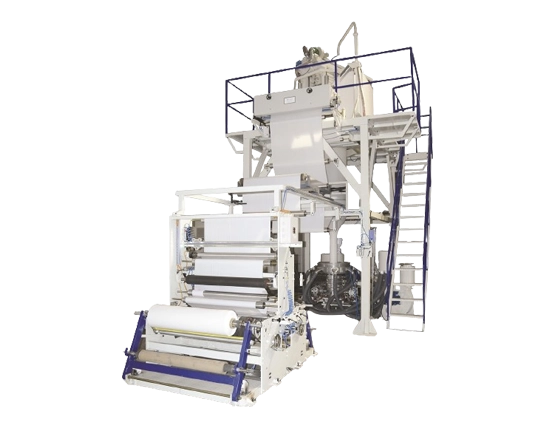

Two Layer ABA Blown Film Plant

The two layer film machine is equipped with two extruders. ABA type two layer film machine can produce two layers of film, each film layer has different material and color. The design pattern provides good color separation and printing effects. Layers are separated from each layer. Blow molding is the most common plastic extrusion process used in the packaging industry and is used to make two- or three-layer films. Two layer ABA machine film, LDPE, LLDPE, HDPE, PBAT, PLA etc. It can be used to produce polymer films using different materials such as The molten plastic is removed from the mold and screw barrel. Air is introduced into the center of the tube to inflate the extruded polymer like a balloon. There is also an air ring that blows cold air onto the thermal film.

Features

- High Output

- Low Power Consumption

- Bubble Control System

- HM / HDPE

- LD / LLDPE

- BIO-DEGRADEABLE

- Helical Gearbox with Thrust Bearing

- Gas Nitride Screw Barrels

- AC Drive Operated Motors

- Spiral Type ABA or AB Die Head for Uniformly Flow

- Oscillating Haul Off unit or Rotary Die Head for Gauge Randomization

Applications

Packaging Films

Grocery Bags

Garbage Bags

Liner Bags

Nursery Bags

LD Milk Pouch

Mulching Films

E-commerce Bags

Product Specification

|

Model |

AE-35-40 |

AE-35-45 |

AE-40-45 |

AE-45-55 |

|---|---|---|---|---|

| Screw Dia layer A | 35 mm | 35 mm | 40 mm | 45 mm |

| Screw Dia layer B | 40 mm | 45 mm | 45 mm | 55 mm |

| Screw L/D Ratio | 28 : 1 | 28 : 1 | 28 : 1 | 28 : 1 |

| Gearbox Type | Helical | Helical | Helical | Helical |

| Screw RPM | 0-100 | 0-100 | 0-100 | 0-100 |

| Die Type | Spiral | Spiral | Spiral | Spiral |

| Filter Type | Candle Type | Candle Type | Candle Type | Candle Type |

| Heating Zone | 11 Zone | 11 Zone | 11 Zone | 12 Zone |

| Nip Roller Size | 660 mm | 1066 mm | 1160 mm | 1320 mm |

| Lay Flat width | 100 mm to 425 mm | 200 mm to 900 mm | 200 mm to 1050 mm | 400 mm to 1150 mm |

| Winder Type | Surface (Optional) | Surface (Optional) | Surface (Optional) | Surface (Optional) |

| Main Motor (HP) | 35-7.5 HP / 40-10 HP | 35-7.5 HP / 45-15 HP | 40- 10 HP / 45-15 HP | 35-15 HP / 55-30 HP |

| Film Thickness | 25 to 100 Microns | 25 to 100 Microns | 25 to 100 Microns | 25 to 100 Microns |

| Max. Output | 40 - 50 Kg/Hr. | 50 - 60 Kg/Hr. | 50 - 70 Kg/Hr. | 70 - 100 Kg/Hr. |

| Connecting Load | 36.5 kw | 43.5 kw | 65 kw | 80 kw |